We were called to perform a swimming pool leak detection for a customer. During the process we performed a leak detection, pressure testing of return lines and a whole pool inspection along with the leak detection. The pool was filled, the water was clear and the equipment was off so we were able to rapidly identify a long list of issues that plagued this 40 year old swimming pool. Also, during the inspection of the pool, we discovered the pool had been literally shortened on one side with a wall installed down the left side of the pool.

When it came to the discussion of repiping the pool, turning it from copper lines to PVC, we opted to route through the other side of the pool, for all the right reasons. We don’t know what kind of backfill, or even concrete, they used more than 30 years ago to perform the construction on this vessel, so it didn’t make sense to try and drill through the unknown. We opted to route the plumbing from the returns and the skimmer back under the deck and to the equipment with the cleanest and least invasive methods to secure the pool and guarantee success.

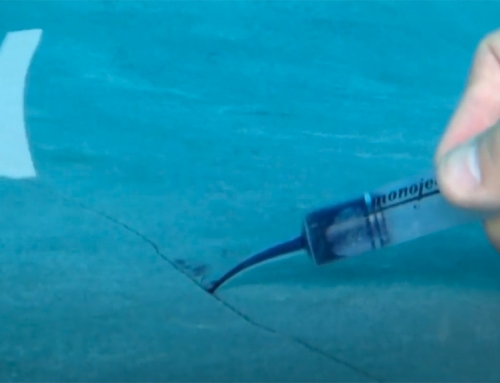

This video above is the first segment in this short series and it takes a look at how we replaced the skimmer and tied it back into the equipment behind the pool. See how we get it done and check back for the next video where we replace the copper lines back to the equipment with new PVC, how we cut and repair the deck and how we returned this pool to service for the customer.

Learn about the equipment and expertise we provide for our CalTech customers so you can be confident your pool will be swim ready after repairs are made. Call 818-436-2953 to discuss your pool and schedule your leak detection to identify issues and get the best recommendations for permanent repairs today.